Making of Amadeo ground floor armed concrete slab

| 04 August 2008 - Comments (1) | Construction |

The armed concrete ground floor of Amadeo A2 is done! That is a big step forward as above will go the walls of the first apartments. Making the slab takes lots of preparation to cast and install the iron reinforcement. As it supports the complete building above, strong iron beams have to be installed to bear all the weigth.

The armed concrete ground floor of Amadeo A2 is done! That is a big step forward as above will go the walls of the first apartments. Making the slab takes lots of preparation to cast and install the iron reinforcement. As it supports the complete building above, strong iron beams have to be installed to bear all the weigth.

Preparing the panels of the cast

The cast of the slab is mainly made out of flat wood panels. On the side exposed to the concrete, the panel is covered with an oil based liquid that prevents humidity from concrete to pass in the wood of the panel.

Covering the wood panels of the cast with an oil based liquid.

Installing the cast of the slab

Wood panels are mounted on a wooden structure supported by metal poles. All metal poles are ajusted at the exact same height and many of them are needed to support the complete floor. Where one wood panel cannot fit, simple wooden planks are used to make the cast.

Wood panels mounted of the wooden structure making the cast of the slab.

Metal poles supporting the wooden structure of the cast.

The cast once finished.

Half of the staircase is covered by the cast as it will be the corridor for accessing the stairs climbing on the first floor.

The metal poles supporting the cast make a small forest in the underground parking below.

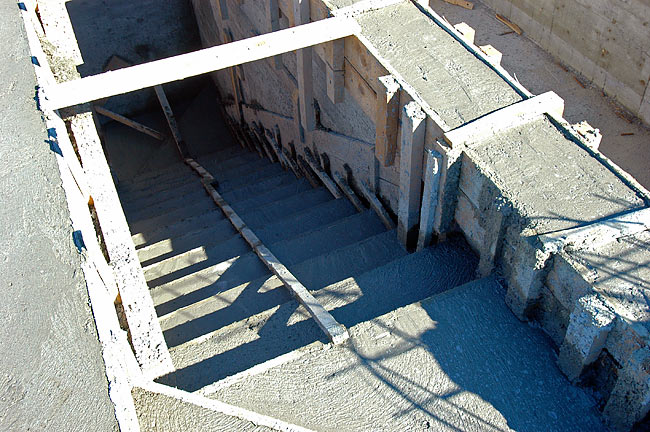

Casting the stairs

For casting the stairs, a first wooden ramp is made with the right slope. Reinforcement is installed directly on the ramp. Then, wooden planks are used to cast each step from the parking up to the ground floor.

Wooden ramp to cast the bottom of the stairs.

Cast of the stairs with the iron reinforcement and wooden planks for casting each step.

The cast of last steps of the stairs.

Stairs cast viewed from the ground floor.

Installing iron reinforcement

The slab is 25cm thick and iron reinforcement is done in 2 layers. The first layer is made of standard iron mesh mounted on plastic distancers. The second layer is made of strong iron bars, positioned to form supportive iron beams in the slab. Those iron beams are placed based on the static calculations made by our static engineer and supervisor.

First layer of iron reinforcement made of standard iron mesh mounted on plastic distancers.

The wooden squares, visible in the reinforcement, are cast for the verticals, where pipes and cables will pass.

Second layer of iron reinforcement made of strong iron bars forming supportive beams.

The supportive beams of the slab connect supportive walls of the underground parking. Some of them are very impressive.

Supportive beams in the ground floor slab.

Detail of the supportive beams in the ground floor slab.

Pouring concrete

Pouring concrete is done quickly together with MARMIL inženjering team.

Starting to pour concrete on the slab.

Pouring concrete progression: pouring, spreading, equalizing.

Smoothing concrete of the slab.

Job done!

The slab is finished. Because of the very hot weather, drying goes very fast. We made sure to water it during the afternoon to prevent cracks.

Amadeo A2 armed concrete slab finished.

Stairs are finished too. We can now climb from the underground parking to the ground floor.

05/08/2008

Stefano

1

Yesss.