Building with POROTHERM - visual guide - corners

| 27 September 2008 - Comments (3) | Construction |

In this second article of our visual guide on POROTHERM, we look at vertical reinforcements and corners. Those are the least obvious aspects of building with POROTHERM. It is important to deal with them properly to avoid the creation of thermal bridges that could ruin the performance of the walls.

In this second article of our visual guide on POROTHERM, we look at vertical reinforcements and corners. Those are the least obvious aspects of building with POROTHERM. It is important to deal with them properly to avoid the creation of thermal bridges that could ruin the performance of the walls.

Vertical reinforcements

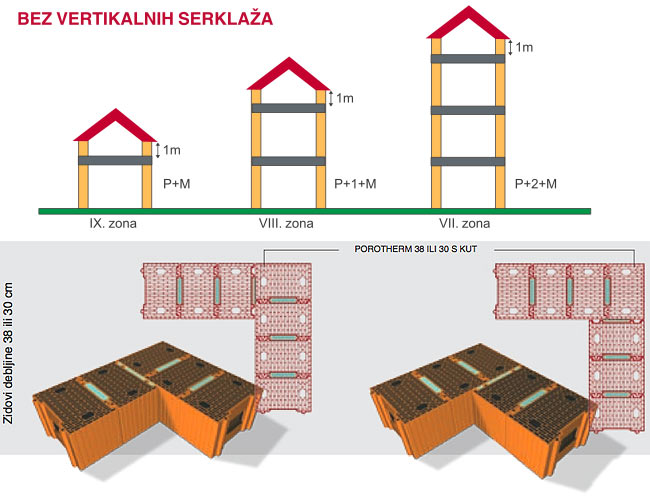

Depending of the height of the building and how seismic is the zone where it is built, it might be necessary to integrate POROTHERM with vertical reinforcements. Belgrade is in seismic zones category VII and VIII. So only individual houses can be built without having vertical reinforcements.

How high a POROTHERM construction can go without vertical reinforcements, depending of the seismic zone (source Wienerberger).

For small residential buildings with 3 floors, like the ones we do, vertical reinforcements are necessary. They are positioned in the corners and at the intersections of the walls.

How high a POROTHERM construction can go with integrated vertical reinforcements, depending of the seismic zone (source Wienerberger).

Those vertical reinforcements are armed concrete columns. They could be cast directly for each corner, but Wienerberger offers a much better and smarter solution based on prefabricated corner elements that interweave in the walls around. That makes the cohesive strength of the construction excellent.

Prefabricated corners

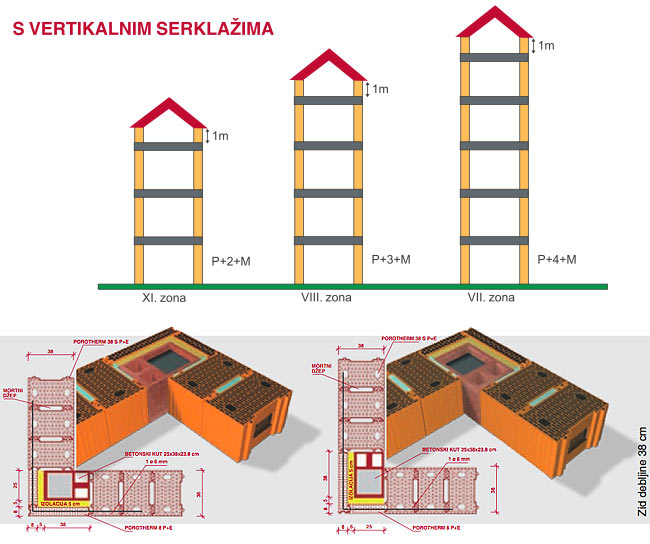

Prefabricated corners have 2 functional parts. One square hollow part that receives iron reinforcement and constitutes the cast for concrete, and one extension that goes into the wall and maintains the cohesion of the construction.

A prefabricated corner 25cm in place (photo Beodom).

That extension of the corner element is turned alternatively in the direction of the walls connecting at this corner.

Example of prefabricated corners going alternatively in the directions of the walls connecting to them (photo Beodom).

Corners thermal insulation

Contrary to POROTHERM blocks, corner elements are filled with concrete and do not provide any thermal insulation. They therefore need to be insulated with additional material. That is why they are less wide than POROTHERM blocks.

There are, in fact, 2 formats for those corner elements. One big, 30cm wide, that can be used inside POROTHERM 30 walls, when there is no need to add insulation (interior corners). One smaller, 25cm wide, that can be used in POROTHERM 38 or 30 walls when thermal insulation is needed.

Interior corners

When the corner is inside, for instance in a POROTHERM 30 wall separating 2 apartments, there is no need to add thermal insulation. Corners 30 are used.

Example of an interior corner, done with a 30cm wide corner element, in the separation wall between 2 apartments. In this example, the wall is made with POROTHERM 30 and the vertical reinforcement is made with corners 30 that match exactly the width of POROTHERM (photo Beodom).

Corners toward the outside

In a POROTHERM 38 wall, when the corner is turned toward the ouside, corners 25 are used together with 5cm of thermal insulation and POROTHERM 8 blocks that protects thermal insulation.

Making a corner in a POROTHERM 38 wall. The corner 25 is used with 5cm of expanded polystyrene and a POROTHERM 8 block (photo Beodom).

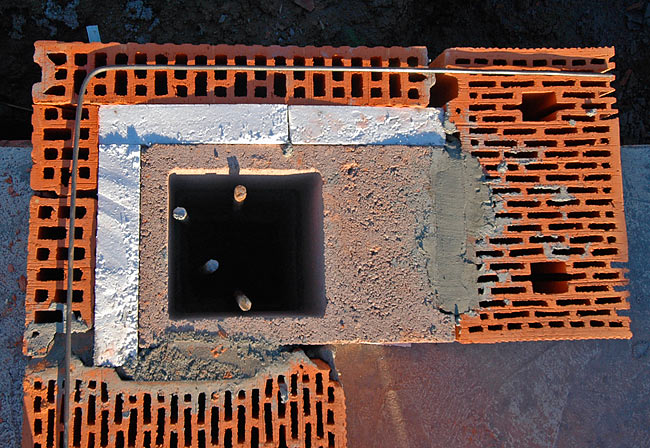

To reinforce POROTHERM 8 blocks, placed around corner elements, small metal beams are used every second row. The metal beam will be taken in the mortar placed before the next row.

A corner 25 in a POROTHERM 38 wall, view from the top. A small metal beam is used to reinforce the POROTHERM 8 blocks placed at the external edge of the wall (photo Beodom).

Corner elements are always aligned on the interior side of the POROTHERM wall.

Corner elements are always aligned on the interior side of the wall. We see the metal beam, used to reinforce POROTHERM 8 blocks, taken into the horizontal joint between the line of blocks (photo Beodom).

Corners toward the inside

Corners toward the inside, can be done without additional thermal insulation by connecting the next POROTHERM blocks to the corner element. That is what has been done on the example below. Polystyrene was still used on one side to fill a space that would have been too small to fit a cut block.

Example of a corner toward the inside. No additional thermal insulation is needed if the next POROTHERM blocks connect to the corner element. In this example, polystyrene was used to fill a gap that was too small to fit a cut block (photo Beodom).

Connections POROTHERM 30 and 38

Corners 25 can be used for the connection of external walls in POROTHERM 38 and interior walls in POROTHERM 30. In that case, 5cm of thermal insulation is used to complement the corner 25 in the POROTHER 30 wall.

Connection between POROTHERM 38 and POROTHERM 30 walls using corner 25. On the right side is the entrance door opening (photo Beodom).

Filling corners with concrete

For each corner stack, it is necessary to make a hole in the first corner element of the stack. That is to be able to remove and clean the corner from excess of mortar that can fall down during the construction of the stack. It is also a window to control the filling of the stack with concrete.

Stack of corners with the hole made in the first corner of the stack (photo Beodom).

Once the iron reinforcement is placed in the stack of corners, pouring concrete is done manually.

Pouring concrete in the stack of corners (photo Beodom).

From the hole in the first corner of the stack, one can control that the concrete filling is done properly.

Controlling the concrete filling of the corners (photo Beodom).

In the last part of this serie of articles, we will look at lintels and cerclage elements.

12/01/2010

ehsan

3

great job

27/09/2008

admin

2

Re: Nice work

27/09/2008

Stefano

1

Nice work