SEEBBE 2009: Rehau, Xella, Wienerberger, Zorka Opeka

| 25 April 2009 - Comments (0) | Construction |

Spring is finally here in Belgrade and together with it came the time of the traditional building fair event, the Sajam Gradjevine 2009. As we are readying to start building Amadeo II, it was the perfect occasion to see what is up in the field. Experience from Amadeo allows us to select what has worked best and also to search for improvements. Here is an summary of few things of interest.

Spring is finally here in Belgrade and together with it came the time of the traditional building fair event, the Sajam Gradjevine 2009. As we are readying to start building Amadeo II, it was the perfect occasion to see what is up in the field. Experience from Amadeo allows us to select what has worked best and also to search for improvements. Here is an summary of few things of interest.

Rehau and Kombo

We have had a very good experience with Rehau and their certified installer Kombo. On Amadeo, we used Rehau water and waste water pipes, underfloor heating and cooling solution, solar panels, water cylinders and geothermal probes. The overall quality of those solutions is matched by the professionalism of the installation.

Rehau and Kombo stand during Sajam Gradjevine 2009 (photos Beodom).

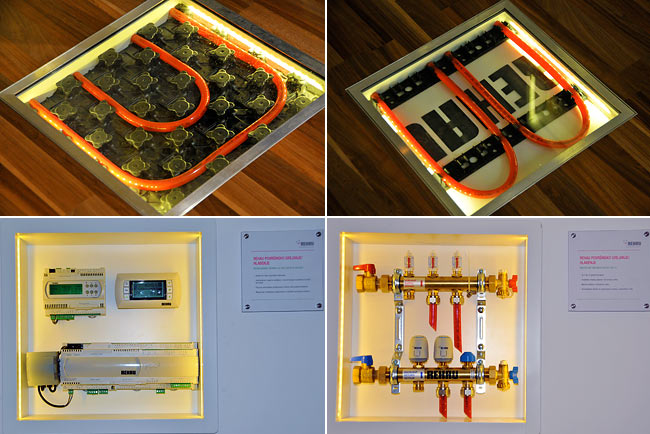

On the fair, Rehau made a nice effort to show their solutions in detail and in action. There was a special tunnel where wall cooling was demonstrated and where others wall and floor heating and cooling solutions were showcased.

Rehau's demonstration tunnel for cooling and heating solutions on Sajam Gradjevine 2009 (photo Beodom)

Rehau's demonstration tunnel showcased solutions: underfloor heating with Vario board and fixation, heating and cooling regulations and heating and cooling distribution manifold (photos Beodom).

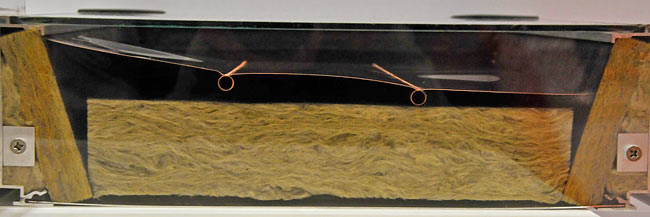

Thermal solar panels were sectioned to show them from inside. An occasion to see that it is indeed simple technology. A coper pipe circulating on a black metal sheet, for better absorption of solar energy, behind a glass. A thick layer of insulation below protects against energy losses. Very educative and interesting.

Rehau SOLECT thermal solar panel section (photos Beodom).

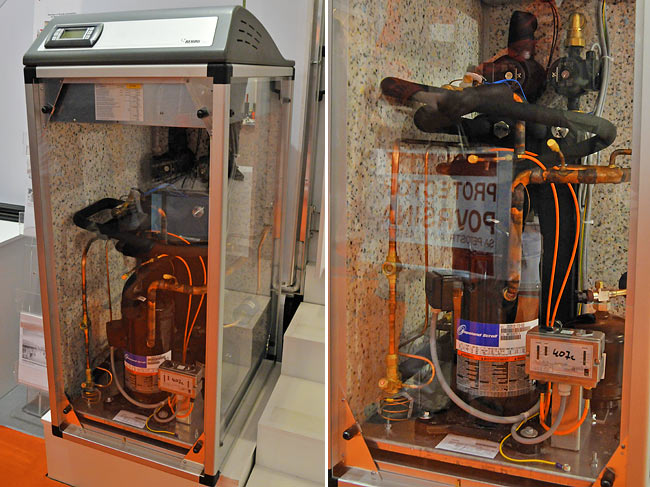

Rehau was also presenting its geothermal heat pump. Two sides were all glass which allowed one to see the inner parts of the pump, most notably the compressor. Again, a very good idea, to demistify the technology and to better explain the principle behind.

Rehau showcase geothermal heat pump (photos Beodom).

Overall, Rehau is offering very attractive sets of solutions for the use of renewable energy in buildings as well as well proven products for heating, cooling, water distribution and waste water pipes.

On another stand, Rehau was also presenting its windows profiles which are well known in Serbia for their quality. It's another area where we will consider its offering.

Xella YTONG

As usual, Xella had a wide presence on the fair. This year, presentation on their stand was done using several touch-screens, which allowed to display lot of information as well as videos and pictures in an interactive way. An interesting innovation.

Xella YTONG stand (photos Beodom).

But the main innovation from Xella was clearly the new Thermoblok 37. At last, Xella proposes in Serbia what has been offered for many years in other countries in Western Europe. This new bloc offers excellent thermal characteristics with a U-value of 0.32 W/m²K, a bit better than a large clay block in the same thickness.

Xella YTONG Thermoblok 37 (photo Beodom).

Of course the comparison with clay blocks of same thickness cannot be avoided and is going to be controversial. If in term of thermal performance, all solutions bring similar results, fired clay and aerated concrete are completely different materials. They have very different characteristics besides having similar thermal conductivity.

Thermal inertia is much greater in clay blocks than in YTONG blocks. Thermal inertia is good to have under temperated climates like in Serbia (this is different for tropical climates). Besides, YTONG is hygroscopic, which means it can absorb lot of water. It has therefore to be covered with waterproof facade which reduces the breathability of the wall as a whole.

Xella YTONG Thermoblok 37 wall (photo Beodom).

Choosing a wall system is a matter of compromise with many variables at play. Right now we see the solution provided by large clay blocks as a better one for new constructions. We are open to hear the arguments of Xella on those various points.

Wienerberger POROTHERM

Wienerberger had a better stand this year than last year, open on 2 sides. During the past few months, the Serbian branch of Wienerberger was completely restructured. The office in Belgrade got closed and the Serbian market is now headed directly from the regional office in Croatia.

Wienerberger stand (photo Beodom).

Besides the classic line of POROTHERM blocks that we know very well, Wienerberger presented their new line of rectified block called POROTHERM PLAN. Those new blocks are perfectly plan so they can be used without mortar.

Wienerberger POROTHERM classic line of blocks (photo Beodom).

Instead of mortar, Wienerberger proposes 2 options to seal lines of blocks together. The first one, thin layer mortar (POROTHERM tankoslojni mort), is a sort of glue that is applied in few millimeters thickness on the complete surface of the line before to put the next line. The second option is based on a new product called POROTHERM DRYFIX.extra. Only two lines of that foam are applied in order to fix the blocks.

Wienerberger POROTHERM PLAN, rectified line of blocks. POROTHERM DRYFIX.extra is showed on the upper block while the thin layer mortar is shown on the line below (photo Beodom).

Those innovations are welcome in Serbia but it will take some time before they can be used widely. Finding skilled workers will not be easy. Building with those rectified blocks really need a perfect realization.

Zorka Opeka KlimaBloc

Zorka Opeka was next to Wienerberger, together with Zorka Keramika.

Zorka Opeka et Zorka Keramika stand (photo Beodom).

This year, Zorka Opeka was presenting KLIMABLOC, its new line of large clay blocks. Since last time we looked at it, Zorka Opeka integrated an interesting solution to solve vertical reinforcements. It is a clay element that is positioned in the corners to cast vertical beams.

Zorka Opeka KLIMABLOC 38 with the new corner element for vertical reinforcements (photo Beodom).

It is a different solution than the concrete element we used with the POROTHERM system, and it has some bright points. One single element instead of 3 (concrete element, POROTHERM 8 and 5cm thick polystyrene), excellent cohesion as the concrete is cast by the block 38 on one side. In term of thermal characteristic, we would need to get some numbers from Zorka Opeka to get an idea.

Closeup on the new corner element for vertical reinforcements (photo Beodom).

Apparently, that same element could also be used to cast lintels in a very interesting way. We have yet to see a good solution for horizontal reinforcements from Zorka Opeka but it's getting there.