SEEBBE 2008/4: comparative look at monolithic wall systems

| 17 June 2008 - Comments (0) | Construction |

In this last article on the 34th Belgrade International Building Trade Fair, we look at the monolithic external wall solutions (wall system without additional thermal insulation). Wienerberger, Nexe and Opeka presented their line of products made of clay, while Xella hammered its YTONG-Termoblok massive marketing effort into the fair.

In this last article on the 34th Belgrade International Building Trade Fair, we look at the monolithic external wall solutions (wall system without additional thermal insulation). Wienerberger, Nexe and Opeka presented their line of products made of clay, while Xella hammered its YTONG-Termoblok massive marketing effort into the fair.

Marketing efforts

Amongst the 4 companies, Xella is clearly the one spending the most money on marketing. It was hard not to see yellow YTONG bags everywhere. Their budget for the fair is probably matching their market share in Serbia. After Xella, Wienerberger was the company doing the biggest marketing effort to present POROTHERM. Wienerberger, despite being the world largest producer of clay bricks for walls, is a challenger in Serbia. Xella and Wienerberger were actually next to each other on the fair.

Although Nexe displayed their ThermoBlocks (TB), they didn't do much more than that. It was hard to get somebody to talk about them. It doesn't seem to be a priority for Nexe. On its side, Opeka had only a small stand lost in a corner of the fair. It is clear they have nowhere near the marketing power of the big guys.

Additionally, only Xella and Wienerberger seems to provide a complete solution to builders, dealing with all aspects of the construction. They both provide a complete wall system and a lot of educational material.

Comparative characteristics of the solutions

So let's look at the blocks proposed by the 4 companies and how do they compare. On the clay blocks side, Wienerberger, Nexe and Opeka all propose blocks of the same size. For external walls, the choice of thickness is 45cm, 38cm or 30cm. For residential buildings, 45cm is simply not economically viable (but might be for individual houses). 30cm is the most popular in Serbia for economical reason, but is simply not sufficient. The thermal characteristics of a wall made of 30cm blocks are not good enough. The best compromise between economics and quality is obtained with the 38cm thick block.

Wienerberger POROTHERM 38 S P+E PLUS and 30 S P+E PLUS, Opeka 38 UT S, nexe TB-38 and Xella Ytong TZB 30.

In 38cm thickness, Opeka 38UT S has the best characteristics, very closely followed by POROTHERM 38 S P+E PLUS. The block TB-38 from nexe is clearly behind. It is rather comparable to the previous generation of POROTHERM and is no more competitive in today market.

| Wienerberger POROTHERM 38 S P+E PLUS | Wienerberger POROTHERM 30 S P+E PLUS | Opeka EUROTERM 38UT S | Nexe TB - 38 | YTONG TZB 30 | |

|---|---|---|---|---|---|

| Width (cm) | 38 | 30 | 38 | 38 | 30 |

| Length (cm) | 25 | 25 | 25 | 25 | 60 |

| Height (cm) | 23,8 | 23,8 | 23,8 | 23,8 | 20,0 |

| Thermal conductivity λ (W/m.K) | 0,139 | 0,140 | 0,138 | 0,160 | 0,130 |

| Thermal transmittance U-value (W/m².K)* | 0,35 | 0,45 | 0,31 | 0,40** | 0,40 |

* Thermal transmittance of the finished wall with insulating mortar as it would be found in a given construction.

** Value extrapolated from λ by us as we couldn't find the manufacturer value.

YTONG is a different beast. It is aerated concrete, made of sand, lime, cement, water and powdered aluminium. YTONG has a smaller thermal conductivity than clay block which gives it an advantage at the same thickness. The problem is that, in Serbia, only 30cm thickness is sold. In Western Europe (France, Germany,...) a block that is 36,5cm thick is sold with an even smaller thermal conductivity (λ=0,10 W/m.K instead of λ=0,13 W/m.K in Serbia).

With a 30cm thickness, and the thermal conductivity of YTONG sold in Serbia, we get a wall with a U-value of 0,40 W/m².K. It is clearly insufficient to meet any good standard of thermal insulation. At least those we are targeting in our constructions. It seems that, what is produced and sold in Serbia, is a product that is far from meeting the same standard of quality and performance as in France or Germany. The fact it uses the same YTONG name just add up to the confusion.

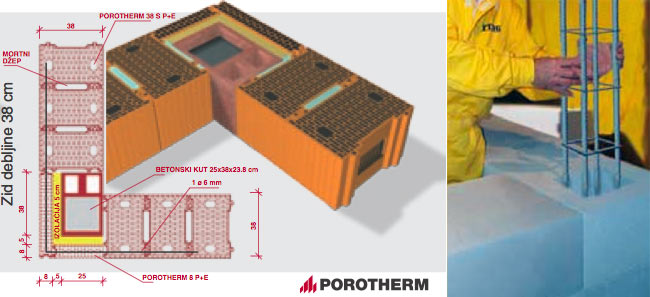

Difference between POROTHERM 38 wall system and YTONG for the vertical reinforcements.

Another important aspect of the monolithic wall construction is the way it deals with horizontal and vertical reinforcements, in order to avoid thermal bridges. Because of its thickness, POROTHERM 38 allows to place a layer of thermal insulation material together with a thin facing brick. YTONG does not offer such a possibility. The resulting thermal characteristics are better on the POROTHERM side.

Wienerberger POROTHERM

Wienerberger was present at the Belgrade International Building Trade Fair for the first time. They had a small space but a good position.

Wienerberger stand

Until Wienerberger starts production in Serbia, POROTHERM bricks are still imported from Croatia. In the meantime, Wienerberger continues producing classic blocks in the factory they bought in Mali Idjos.

Wienerberger line of products in Serbia.

Wienerberger displayed a small wall made of POROTHERM 38 S P+E PLUS. They didn't make the horizontal joins between the lines of blocks. Right now, those horizontal joins are made of a layer of thermal mortar. Later, Wienerberger will make available a technic already in place in France, where the thermal mortar is replaced by an ultra thin layer of glue. That effectively suppress the horizontal join. For this technic, blocks have to be rectified to guarantee a perfectly flat surface (as there is no mortar to compensate eventual irregularities). They will start the production of rectified POROTHERM in Croatia later this year or next year.

Wienerberger POROTHERM 38 S P+E PLUS wall.

Nexe TB

Nexe had a large open space at the fair to present their various products. Their ThermoBlock line TB was relegated in a corner.

Nexe stand

Like Wienerberger, nexe proposes various sizes for different uses although they did not show brick for partition walls.

Nexe blocks - line of products

The closest equivalent to POROTHERM 38 S P+E PLUS is TB-38 but it is, in fact, more similar to the previous generation POROTHERM. There would be little reason to use TB-38 over POROTHERM today.

Nexe TB 38

Opeka Euroterm

Opeka had a small space, far from the other 3. Just enough place to display their Euroterm line of products.

Opeka stand

Opeka proposes Euroterm 38 UT, which is very similar to nexe TB-38, and not interesting in term of thermal performance for its thickness. It doesn't come close to POROTHERM. But the really interesting block from Opeka is Euroterm 38 UT S.

Opeka Euroterm line of products (left), Euroterm 44 UT and 38 UT (right).

Euroterm 38 UT S and 30 UT S have a very particular structure which gives them the best thermal performance of all clay blocks described here. It is the most interesting of all.

Opeka Euroterm 38 UT S and 30 UT S

Xella YTONG building system

Xella had a large open space solely dedicated to the YTONG wall system.

Xella stand

Xella tends to present the YTONG Termoblok concept as the best building solution. But in its thickness of 30cm and with a U-value of 0,40 W/m².K, it doesn't match the most basic requirements in term of thermal performance for advanced norms. Note that Xella does have much better products in those countries such as France that require better thermal performance.

Xella Ytong termoblok concept.

That is the aspect of Xella's marketing in Serbia we dislike the most. It is a one sided story, where everything is arranged to make it compelling. But the story doesn't hold when confronted to simple facts. If we could get in Serbia the same YTONG block in 36,5cm thickness with a thermal conductivity of 0,10 W/m.K as the one sold in France, it would be a very different story. YTONG would be one of the most compeling system.

Like last year, Xella built a small house at the entrance of the fair to show the YTONG concept in action.

Ytong house at the entrance of the fair

When you look closer, it seems that YTONG blocks sold in Serbia do have a problem of sturdiness as they crack and get damaged easily on the edge.

Detail of the Ytong wall