How to evaluate and compare thermal insulation solutions

| 02 May 2007 - Comments (1) | Construction |

In the first installment,

we explained the physics of thermal insulation and heat transfer via conduction, convection and radiation. In this installment, we decribe the important parameters used to measure and compare the quality of thermal insulation solutions. In a follow up installment, we will see how comfort in summer is affected by thermal insulation.

In the first installment,

we explained the physics of thermal insulation and heat transfer via conduction, convection and radiation. In this installment, we decribe the important parameters used to measure and compare the quality of thermal insulation solutions. In a follow up installment, we will see how comfort in summer is affected by thermal insulation.

Thermal conductivity (k or λ)

The transmission of heat from ambiant air to walls, floor or roof occurs via convection and radiation. Once heat entered the material, heat transmission occurs mainly via conduction, although that, depending of the material, convection and radiation can still exist.

Heat conduction, is therefore the component that thermal insulation materials used in construction will be able to reduce the most. Thermal insulation materials will reduce the loss or gain of heat by preventing heat conduction to happen in their fabric. The total effect depends on the material used and on its thickness.

The physical property that measures the effectiveness of a material to conduct heat is called thermal conductivity. It is expressed in Watt per meter.Kelvin (W/mK). Very often, you will see that number given on insulation material specifications. The smaller the number, the better the material is regarding thermal insulation.

Thermal conductivity is an intensive physical property of the material; it depends only on the material itself and not on anything else (thickness, size). The thermal conductivity of a material is not easy to measure. And between a measure done in a laboratory, in ideal conditons, and what you will get in your house, in less than ideal conditions, there is usually a difference.

Here a list of some typical thermal insulation materials, and some large construction blocks which do not necessitate an additional layer of thermal insulation, with their thermal conductivity based on the claim of their respective manufacturer.

| Material | Thermal conductivity (W/mK) |

|---|---|

| Air | 0.025 |

| Expanded polystyrene of various density | |

| Austrotherm EPS® W 15 (15 kg/m²) | 0.041 |

| Austrotherm EPS® W 30 (30 kg/m²) | 0.035 |

| Tarolit EPS 50 (12 kg/m²) | 0.041 |

| Tarolit EPS 200 (30 kg/m²) | 0.031 |

| Extruded polystyrene | |

| Austrotherm XPS® TOP® 30 SF | 0.035 |

| Glass mineral wool | |

| ISOVER KL 35 (laboratory value) | 0.035 |

| ISOVER KL 35 (design value) | 0.041 |

| Rock mineral wool | |

| Generic rock mineral wool | 0.032 to 0.040 |

| Wood fiber | |

| Tarolit | 0.110 |

| Cellulose | |

| DÄMMSTATTs CI 040 | 0.038 |

| Construction blocks with no need of additional thermal insulation | |

| Wienerberger POROTHERM 38 S P+E (regular mortar) | 0.220 |

| Wienerberger POROTHERM 38 S P+E (insulating mortar) | 0.180 |

| Wienerberger POROTHERM 38 S P+E PLUS (regular mortar) | 0.190 |

| Wienerberger POROTHERM 38 S P+E PLUS (insulating mortar) | 0.139 |

| Opeka EUROTHERM 38 UT (regular mortar) | 0.233 |

| Opeka EUROTHERM 38 S (regular mortar) | 0.138 |

| Nexe TB-38 (regular mortar) | 0.160 |

| Xella Ytong | 0.130 |

Thermal conductivity of various building components.

Most likely, the numbers above are given at manufacturing time. When you use a given material in construction, you have to consider how the thermal conductivity of that material degrades over time. In addition, the quality of the application of the material has to be taken into account. Last, the thermal conductivity of a material may vary with the ambient temperature and the amount of humidity in the air and in the material itself.

One big advantage of construction blocks, is that their characteristics are stable in time and under most conditions. This is not the same for polystyrenes and mineral wools.

Thermal resistance (R-value)

Thermal conductivity allows comparing materials and their ability to conduct heat. In practice, that alone is not enough to judge the quality of a given thermal insulation solution. The thickness of the material applied has to be taken into account.

That is the reason we use another measure called thermal resistance or R-value. It is simply the thickness of the material divided by the thermal conductivity of that material:

R = d/k

where d is the thickness. Its unit is m²K/W.

For instance, 5 cm of Austrotherm EPS® W 15, a thickness often found on houses in Serbia, will provide a R-value of 0.05/0.041 = 1.22 Km²/W. A Wienerberger POROTHERM 38 S P+E PLUS that is 38 cm thick will give a R-value of 0.38/0.139 = 2.73 Km²/W. The greater the R-value, the better the solution is regarding thermal insulation.

Of course, as we will see later, when evaluating the thermal resistance of a complete wall, all components of the wall must be taken into account and not just the insulation layer.

Thermal conductance (C)

In term of thermal insulation, thermal resistance gives a counterpoint of thermal conductivity: bigger thermal resistance = better while smaller thermal conductivity = better. For that reason, another measure, called thermal conductance is also used. Thermal conductance is simply the inverse of thermal resistance: C = 1/R. Its unit is W/m²K.

Very often, you will see the thermal conductance assimilated to the U-value defined below. It is not exact as U-value is a more subtle and complex parameter.

Total thermal resistance (RT)

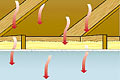

As we mentioned above, when evaluating a thermal insulation solution, all components of the solution have to be taken into account. For instance, for a wall made of inner surface + clay block + mineral wool + air space + brick + outer surface, the R-value of each component has to be considered. In addition, because the exchange of heat between the wall and the ambient air occurs via convection and radiation, the heat transfer coefficient of the wall surface indoor and outdoor have also to be taken into account.

The total thermal resistance does just that. It represents the sum of all thermal resistances for each component of the building section, including the surface thermal resistance of both sides of the section. Its unit is m²K/W.

The surface thermal resistance of a building section represents the resistance to heat transfer via convection and radiation between the ambient air and the surface of that building section. It is the inverse of the surface conductance (h) for that surface. Ri represents the surface thermal resistance from the indoor surface of the section. Re represents the same parameter for the outdoor surface of the section.

RT, the total thermal resistance of the building section, is the sum of Ri, Re and all thermal resistances of the components of that section (figure below).

Total thermal resistance of a building section. It is the sum of the superficial thermal resistances and of all thermal resistances of each component of the building section. (source Architecture et Climat, Université catholique de Louvain)

Thermal transmittance (U-value)

The thermal transmittance or U-value represents the amount of heat, transfered through a building section, between the indoor and outdoor climate, for a unit of surface and temperature. Its unit is W/m²K. It is also called the overall coefficient of heat transmission.

U-value is simply equal to the inverse of the total thermal resistance.

U = 1 / RT

Simply put, U-value rates the energy efficiency of the combined materials in a building component or section. The smaller the U-value, the better the solution is in term of thermal insulation and energy saving.

Total thermal resistance and thermal transmittance are used to rate and compare building solutions. They are also used in various construction norms around the world to set the acceptable standards for new constructions. Below we give the standards set by the French norm RT 2000 (France has a similar climate as Serbia) that should be applied in Serbia as well for quality constructions. Note that the numbers below set the minimum legally acceptable for new constructions in France. Better is always an option for comfort and heat saving.

| Building section | RT (m²K/W) | U (W/m²K) |

|---|---|---|

| Walls | 2 to 3 | 0.5 to 0.33 |

| Floors | 2 to 3 | 0.5 to 0.33 |

| Ceiling | 4.5 to 5 | 0.22 to 0.2 |

| Roof | 4.5 to 6 | 0.22 to 0.17 |

French norm RT 2000 minimum values for thermal performance of different building sections.

Conclusion

We presented the main parameters used to talk about the efficiency of thermal insulation solutions. We saw that, to evaluate the thermal insulation of a complete building component, all of its parts have to be taken into account. By extension, to evaluate the energy efficiency of a complete house, walls, floor, ceiling, roof, windows, all parts have to be considered. That is why there is no reason to pay much more to better insulate the walls if it is to save on the windows and get bad ones regarding insulation. All parts have to be consistent.

Care must be taken to avoid thermal bridge (parts that are not or less insulated) in the construction not to degrade the global performance of the thermal insulation.

Our advice would be to think of one house as a complete system and take care of all parts rather than focus on the choice of one material because of its theoretical k-value. Whatever the manufacturer says, the house is the sum of all of its parts. The worst part will be the weak point of the system and can have a greater negative impact than the positive impact of the best parts.

19/02/2009

Granville Jenkins

1

Comment