Building with POROTHERM - visual guide - lintels

| 25 May 2009 - Comments (1) | Construction |

In this last article of our POROTHERM building visual guide, we focus on doors and windows lintels, and we look at cerclage elements that are used as a cast and thermal break around slabs. Lintels for Windows with integrated shutters are the most delicate to realize as we will describe in this article.

In this last article of our POROTHERM building visual guide, we focus on doors and windows lintels, and we look at cerclage elements that are used as a cast and thermal break around slabs. Lintels for Windows with integrated shutters are the most delicate to realize as we will describe in this article.

Doors lintels

Door lintels are done using precast lintels from Wienerberger. They are very easy to use and come in several lengths and in 2 widths. One format is 10cm wide and 8,5cm high. It offers lengths from 0,75m to 3,25m by increment of 0,25m. The other format is 12cm wide and 6,5cm high. It offers lengths from 0,75m to 3m by increment of 0,25m.

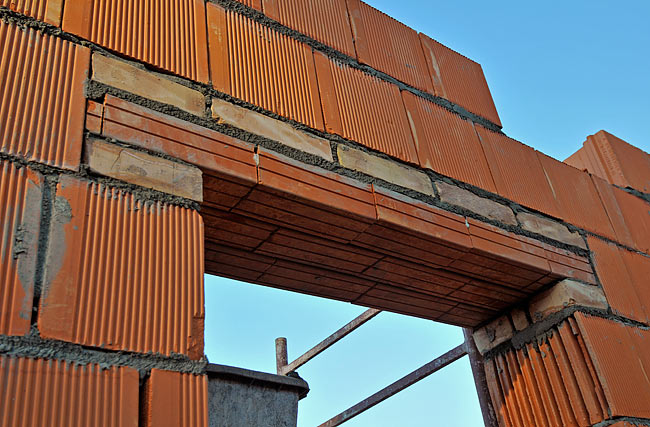

Positioning Wienerberger precast lintels above a door opening (photo Beodom).

For interior walls, which are 30cm thick, we use three 10cm wide precast lintels. They are positionned at the right height and made perfectly horizontal.

Positioning the last precast lintels above a door opening (photo Beodom).

Adjusting lintels above a door opening (photo Beodom).

Once the 3 lintels have been positionned, the next line of POROTHERM blocks can be put in place.

Putting in place the next line of POROTHERM blocks above the lintel (photo Beodom).

To fill the remaining space above the lintels up to the next full line of blocks, it is possible to use cut POROTHERM blocks or bricks, depending of the configuration. In this example, full bricks have been used. In term of thermal insulation, this solution is acceptable as the other side of the door is the staircase where the temperature will only be moderatly cold.

Filling the space above the lintels with full bricks (photo Beodom).

The way bricks are used really depends on the configuration of door openings. Below are 2 other examples.

Examples of door openings once finished with Wienerberger precast lintels (photos Beodom).

Windows lintels with rolling shutters

Regular window openings can be done exactly in the same way as door openings, using 3 lintels. On a wall with POROTHERM 38, 12cm wide lintels can be used with a small 1cm wide space between them. On Amadeo, we had windows with integrated rolling shutters and this simple solution could not apply. So we came up with our own solution.

Window opening with space for the rolling shutter (photo Beodom).

The box for rolling shutters was 21cm wide and 20cm high. On a 38cm thick wall, we had left 17cm in front. In that space, we fitted 5cm of thermal insulation (Tarolit) and one lintel 12cm for the support of the higher part. So in the thickness of the wall, the window opening was divided in 2 parts. The higher part in front of the shutter supported by on lintel, and the thinner part on top of shutter that was cast and made with reinforced concrete.

Window opening with rolling shutter from the outside. All the outside part is insulated with 5cm of Tarolit (photo Beodom).

We prepared several casts that could be reused on several openings. The high part on the back (toward the outside) was closed with 5cm of thermal insulation. The shallow part on the front (toward the inside) was also closed with 5cm of thermal insulation in order to provide continuous insulation inside of the apartment as the shutter box itself is insulated on the same side.

Cast for the lintel of a window opening with integrated shutter (photo Beodom).

Lintels of window openings with integrated shutter filled with concrete (photo Beodom).

The thickness of the shallow part on top of the shutter box varies function of the width of the opening. It is a reinforced concrete beam that has to be strong enough to support the line of POROTHERM blocks above it. Below is the lintel for a window opening that is 2 meters wide.

Lintel for a 2 meters wide window opening with integrated shutter, viewed from inside (photo Beodom).

Lintel for a 2 meters wide window opening with integrated shutter, viewed from outside (photo Beodom).

Cerclage elements for insulation of floor slabs

Wienerberger proposes special elements to place around slabs. Those clay elements give the same surface as the blocks on the outside and provide 7cm of thermal insulation. They make the concrete cast for the slab and prevent thermal bridges around the slab at the same time.

Wienerberger cerclage elements for slabs (photo Beodom).

The elements are placed around the slab on a layer of mortar. They are 20.8cm high. With the layer of mortar below, it makes the slab 22cm high. In term of thickness, the elements are 13cm (6cm for the brick and 7cm for the thermal insulation). On a POROTHERM 38 wall, that leaves 25cm for the iron beam which is sufficient.

Wienerberger cerclage elements in place on a 38cm wall with the iron beam in front (photos Beodom).

The concrete can be poured directly on the slab at the level given by cerclage elements. Below is the slab once finished.

Finished slab with cerclage elements (photo Beodom).

30/11/2010

adeel shahzad

1

Re: Building with POROTHERM - visual guide - lintels