Energy efficiency

One of the key concepts of Beodom is energy efficiency: spending less energy for better comfort. Energy efficiency comes with excellent thermal insulation and smart choice of building materials. Beodom builds with large clay blocks, uses outstanding thermal insulation, takes great care of thermal bridges and uses windows with low-e glazing filled with argon.

External walls

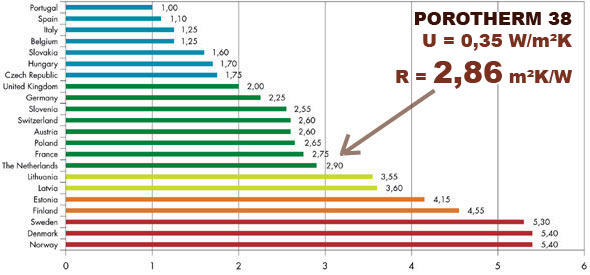

External walls of Beodom's constructions are made of POROTHERM 38 S P+E PLUS which provides excellent natural thermal insulation and thermal inertia. That thermal insulation is better than what is required in the most demanding norms for similar climate, such as the French one, and much better than Serbian standards.

Applied thermal resistance in insulation of walls for new constructions in Europe in 2004 (source Eurima).

A wall made of POROTHERM 38 S P+E PLUS with thermal mortar has a Thermal transmittance (U) of 0.35 W/m²K. That makes the Total thermal resistance (R) equals to 2.86 m²K/W.

Building a wall with POROTHERM 38 S P+E PLUS and Baumit ThermoMörtel 50 (photo Beodom).

Performance of a POROTHERM 38 wall is excellent in winter, thanks to its excellent thermal insulation characteristics. In addition:

- its thermal insulation capacity stays unchanged over time

- humidity can evacuate easily without accumulation (no mould)

- it absorbs and releases heat acting as a regulator of the inside temperature

- and its mass provide thermal inertia needed for comfort in summer.

Avoidance of thermal bridges

Another aspect of thermal insulation is to prevent thermal bridges that can be the cause of heat loss. We use the right solutions to avoid or attenuate thermal bridges and reduce heat loss to a minimum.

Floor slabs

The thickness of POROTHERM 38 allows to avoid thermal bridges on the floor slabs by placing a cerclage element with thermal insulation all around the concrete floor. This solution prevents most of the heat loss. Only balconies remain a problem that we address with Schöck Isokorb (see below).

POROTHERM cerclage elements to prevent thermal bridges on concrete slabs (photo Beodom).

Balconies

Thermal bridges created by balconies and terraces are certainly the most overlooked ones is residential buildings. Excellent solutions exist to prevent them. One of them from Schöck is a load bearing thermal insulation element that is placed in the concrete to stop the heat flow going through concrete elements.

Connection between Schöck Isokorb and POROTHERM cerclage elements (photo Beodom).

Schöck Isokorb Type K 10/7 positioned on the balcony (photo Beodom).

Vertical reinforcements

For vertical reinforcements, we use POROTHERM corner elements. They are specially designed to fit in a POROTHERM 38 wall together with 5cm of thermal insulation and a POROTHERM 8 brick.

Insulation of vertical reinforcements with POROTHERM corner elements (photo Beodom).

Walls

Another source of thermal bridges are joints between blocks. In the case of POROTHERM, there are no vertical joints. The only joints are the horizontal ones, between two layers of blocks, that is about 1 cm thick. For our constructions, we use a special thermal insulating masonry mortar (Baumit ThermoMörtel 50) preserving the excellent thermal characteristics of the blocks.

A POROTHERM 38 wall. This is no vertical joints and the horizontal joints are made with thermal mortar Baumit ThermoMörtel 50 (photo Beodom).

Other situations

For all other situations, where we need to cast concrete slabs or beams directly, we take care to prevent thermal bridges by insulating the concrete. We always try to find the best solution that minimize thermal losses depending of the situation. For concrete insulation, we use Tarolit or any other equivalent product.

Insulation of a concrete slab connecting on a wall inside an apartment (photo Beodom).

Insulation of a concrete vertical pole at the corner of 2 POROTHERM 38 walls. The inside corner (not visible) is also insulated (photo Beodom).

Insulation of a concrete lintel seen from the exterior side (photo Beodom).

Roof

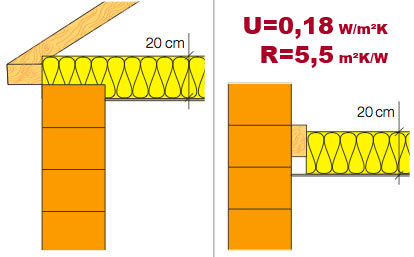

Thermal insulation on the ceiling. Left: false ceiling just below roof, right: lower false ceiling (source Wienerberger).

Hot air going naturally up, the thermal insulation of the roof is a major component of a good thermal insulation. For the roof, we use Knauf Insulation rock wool as insulating material.

When possible, we place the insulating material directly on the ceiling. For the part of the ceiling that is directly under the roof, the insulating material is applied directly under the roof. In both case, we use a 20cm thick layer, or two 10cm thick layers of the same material.

That gives a thermal transmittance around 0.18 W/m²K.

Windows: PVC frame, low-E glazing, argon fill

Windows are a key component of a low-energy construction. Ideally, they should have a U-factor as close as possible to the one of the walls. If not performant enough, they will cause dramatic heat loss and increase the heating bill.

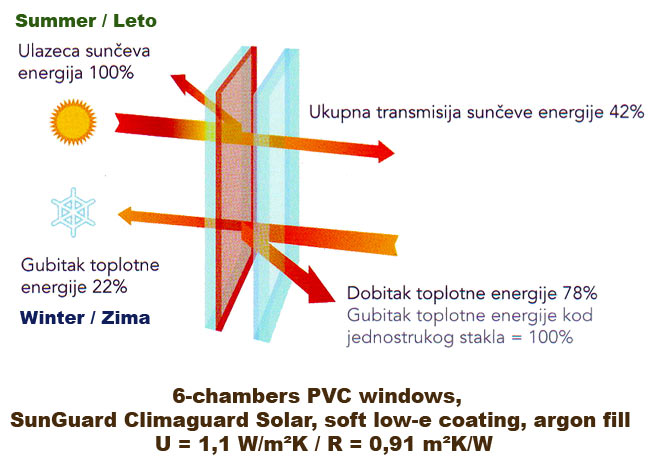

The modern standard is to use low-E glass with argon fill. Low-E stands for low emissivity glass and is a type of insulating glass. Compared to regular glass, low-E glass have a special metal coating on one side, technically known as a low emissitivity, or low-E coating. It increases the energy efficiency of windows by reducing the transfer of heat or cold through glass: the apartment stays warmer in winter, and cooler in summer.

Low-E coating works by blocking heat wave radiation. In summer time, it reduces the amount of heat transferred through the window by filtering the sun's short-wave radiation. In winter time, it reflects the inside long wave radiation produced by the inside heat (source Guardian SunGuard).

Argon is a gas that avantageously replaces air between the two glazing of a double-glazing window. Because of its low thermal conductivity, it increases the thermal performance of the window. By combining low-E coating and argon fill, it is possible to increase the thermal performance of the window by 50 to 60%. Yet, the additional cost per window is rather small. This is a typical example where is small effort yield a big gain.

Beodom uses 6-chambers PVC frame for the window and Guardian SunGuard Climaguard Solar for the low-e glazing, achieving an excellent U Value of 1.1 W/m²K.

Insulation of pipes

See the quality page on installation for more details about pipes insulation.

Energy efficiency

Energy efficiency