Zorka Opeka KLIMABLOC: a promising new competitor to POROTHERM

| 03 October 2008 - Comments (0) | Construction |

Zorka Opeka, already famous in Serbia for facing bricks and other fired clay products, launched a new line of products called KLIMABLOC. These new blocks are aimed to build walls which do not need any additional thermal insulation material, like Wienerberger POROTHERM. KLIMABLOC is Austrian design and technology and has everything to shake up the Serbian market.

Zorka Opeka, already famous in Serbia for facing bricks and other fired clay products, launched a new line of products called KLIMABLOC. These new blocks are aimed to build walls which do not need any additional thermal insulation material, like Wienerberger POROTHERM. KLIMABLOC is Austrian design and technology and has everything to shake up the Serbian market.

Development of KLIMABLOC in Serbia

In 2003, Zorka Nemetali was bought by Alas International as part of a privatization. It was renamed Alas Holding in 2007. Alas Holding a.d., is part of the bigger Austrian company Asamer Holding AG. Since 2006, Asamer Holding invested many millions of euros to modernize and develop production in all properties of Alas Holding: Zorka Opeka, Zorka Keramika, Zorka Alas Kamen and Zorka Održavanje.

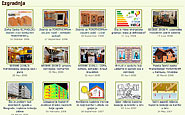

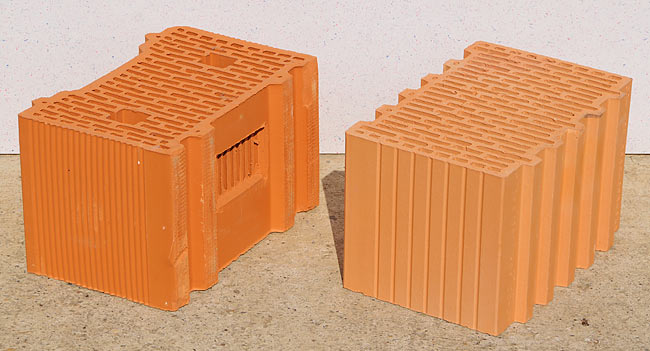

3 products from KLIMABLOC (left to right): KLIMABLOC 25 GT, KLIMABLOC 12 GT and KLIMABLOC 38 GT (photo Beodom).

In 2008, Alas Holding joined with the Austrian company Ziegelwerk Pichler Wels KG, for the production of KLIMABLOC in Serbia. KLIMABLOC is a complete line of large clay blocks that allow to build monolithic walls, with excellent thermal characteristics and no additional thermal insulation material (like Wienerberger POROTHERM). KLIMABLOC has been developed by Ziegelwerk Pichler in Austria and is currently sold there. It is the best of Austrian design and technology that is now produced under license by Zorka Opeka in Serbia.

Alas Holding and Zigelwerk Pichler invested several million euros to make the factory producing KLIMABLOC the most modern one in the region. Production of KLIMABLOC just started on this new production line.

KLIMABLOC line in Serbia

Currently, in Serbia, Zorka Opeka proposes 4 products under the KLIMABLOC line:

| name | use | dimensions in cm |

weight in kg |

|

|---|---|---|---|---|

|

|

KLIMABLOC 38 GT |

External load bearing walls. KLIMABLOC 38 GT is equivalent to POROTHERM 38 S P+E PLUS. |

38x25x23,8 | 16,7 |

|

|

KLIMABLOC 30 GT |

External/internal load bearing walls. KLIMABLOC 30 GT is equivalent to POROTHERM 30 S P+E PLUS. |

30x25x23,8 | 13,1 |

|

|

KLIMABLOC 25 GT |

External/internal load bearing walls. If used for external walls, thermal insulation material must be added. |

25x38x23,8 | 15,8 |

|

|

KLIMABLOC 12 GT |

Partition walls. |

12x38x23,8 | 10,4 |

A comparative look at KLIMABLOC and POROTHERM

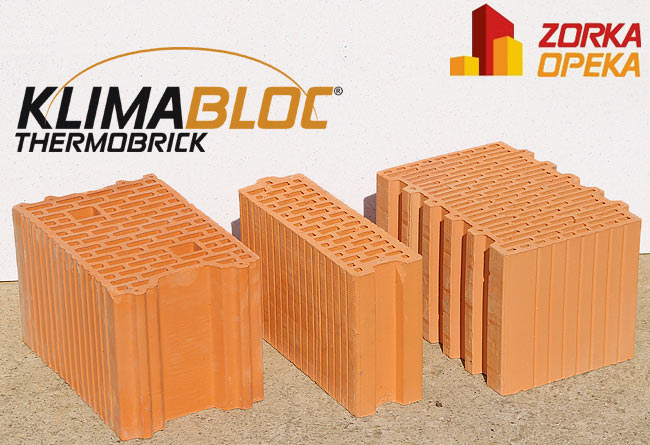

KLIMABLOC 38 GT is identical in dimensions as POROTHERM 38 S P+E PLUS. It also shares the same internal structure: the number of lines of cells is 23 in both case. In POROTHERM 38 S P+E PLUS there is the presence of two holes to facilitate handling.

Comparative size and internal structure of Wienerberger POROTHERM 38 S P+E PLUS (left) and Zorka Opeka KLIMABLOC 38 GT (right) (photo Beodom).

The main differences are in the connecting system between blocks and in the type of clay.

Connecting system

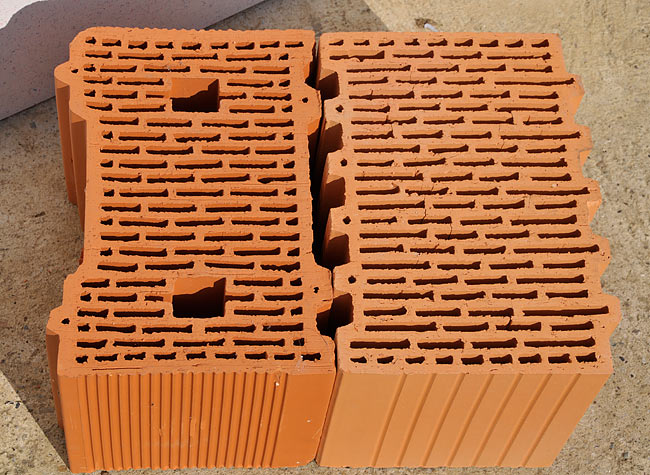

POROTHERM 38 has only 2 connective elements on the side. The main aspect of POROTHERM is the presence of the antiseismic grid that is filled with mortar during construction. KLIMABLOC 38 has 5 connective elements, making the connection between 2 blocks strong, without the presence of the antiseismic feature.

Comparison of the connecting system between POROTHERM 38 S P+E PLUS (left) and KLIMABLOC 38 GT (right) (photos Beodom).

The merit of POROTHERM's antiseismic feature is debatable. From our experience, filling the antiseismic gap between each 2 blocks uses a lot of mortar. As we use thermal mortar to preserve the thermal characteristics of the wall, that additional use of mortar add up to the cost of using POROTHERM. Because the mortar is thick, not much can go inside of the grid anyway. Last, because we use vertical reinforcements, one can wonder if this feature is needed at all. May be it has more impact when vertical reinforcements are not used.

We see the connecting system of KLIMABLOC 38 as being better than the one from POROTHERM 38. It uses no mortar and is yet very strong thanks to the 5 connective elements. In term of thermal performance, the connecting system of KLIMABLOC 38 is also better, leaving no space and no mortar.

Quality of clay

The quality of clay used by Zorka in Šabac is well known all over Serbia. All fired clay products (from ceramic tiles, facing bricks and construction blocks) from Zorka beneficiate from that quality. Thanks to its particular composition, that clay is naturally porous giving the finish product its excellent properties.

For POROTHERM blocks, produced in Karlovac, Croatia, porosity of blocks is achieved by mixing wood particles to the clay. The clay is not porous enough by itself. These wood particles burn during the firing in the klin, leaving porosity in the block.

Color comparison between POROTHERM 38 S P+E PLUS (left) and KLIMABLOC 38 GT (right) (photo Beodom).

A simple look at the color of POROTHERM and KLIMABLOC shows that the mineral composition of the clay is not the same. The red color comes notably from the presence of iron oxide in the clay.

KLIMABLOC 38 and POROTHERM 38 weight about the same, around 17kg.

Thermal performance

The same block in Austria, Klimabloc 38 VZ S, as the one produced in Serbia is given with a thermal transmittance or U-value of 0.33 W/m²K. Tests are underway for Klimabloc 38 GT produced in Serbia, but one can expect very similar result as only the clay differs.

POROTHERM 38 S P+E PLUS is given with a U-value of 0.35 W/m²K. Therefore, Klimabloc 38 will probably be better than POROTHERM 38 in term of thermal performance.

Conclusion

Zorka Opeka created an extremely attractive product line with KLIMABLOC. It is Austrian design and technology, very good quality clay, excellent thermal characteristics and best of all, produced locally. Because of that, KLIMABLOC is cheaper than POROTHERM that is currently imported from Croatia.

The only negative aspect we see in this new KLIMABLOC line, is the lack of some elements in order to provide a complete building solution. In particular, corners, lintels and cerclage elements are missing at the moment. But those elements already exist in the KLIMABLOC line in Austria. So, it is just a matter of time and market demand before Zorka Opeka produces them as well. We are already in contact with them to follow up on that.

Update on 07/10/2008

Wienerberger told us that they produce blocks, similar to KLIMABLOC, in Hungary. These blocks are imported and sold in Serbia along those imported form Croatia. Coincidentally, we received a shipment of these blocks from Hungary in size 30. They are called Porotherm 30 N+F PROFI.

Wienerberger Porotherm 30 N+F PROFI imported from Hungary in Serbia (photos Beodom).

Having had the chance to work with them, we can definitely say that we prefer the format proposed by Zorka with KLIMABLOK and by Wienerberger Hungary over the one from Wienerberger Croatia. Wienerberger Croatia actually started to produce a new type of POROTHERM called PROFI that is laser rectified and is used without malter but with glue. That new type also got rid of the antiseismic feature.

It will be interesting to watch which format Wienerberger Serbia will settle on once they start production in their factory in Mali Idjos. Price wise, only a local production will be competitive with Zorka KLIMABLOC.