SEEBBE 2010: Rehau, Zorka Opeka, Liapor and energy efficiency conference

| 24 April 2010 - Comments (0) | Construction |

The main novelty during this new edition of the Sajam "Građevinarstvo 2010" was the conference on energy efficiency organized during the event. The conference is a testimony of the growing importance of the topic of sustainable development in Serbia. Besides the conference, there were few novelties that we noticed.

The main novelty during this new edition of the Sajam "Građevinarstvo 2010" was the conference on energy efficiency organized during the event. The conference is a testimony of the growing importance of the topic of sustainable development in Serbia. Besides the conference, there were few novelties that we noticed.

Energy efficiency conference

Several officials from the Serbian government were at the conference to present their work on the front of the regulation for the energy efficiency of new constructions. An energy certificate, compulsory for all new constructions, will be introduced. Companies offering solutions in the field of energy efficiency and renewable energy also presented their solutions.

The poster of the conference on energy efficiency during the Sajam Građevinarstvo 2010 (photo SEEBBE 2010).

Jasminka Pavlović, Senior Adviser in the Ministry of Environment and Spatial Planning, opened the conference on the first day and presented the work in her Ministry regarding energy efficiency measure in the building sector. New regulations and new requirements are under way in Serbia. The energy certification of new buildings will become an integral part of their technical documentation. Things are definitely moving in the right direction in Serbia and the first results will appear before year end.

Jasminka Pavlović, Senior Adviser in the Ministry of Environment and Spatial Planning of the Republic of Serbia (photo Beodom).

Milena Gojković-Mestre, Director of Beodom, was invited on the first panel to talk about the experience of Beodom in realizing the 2 first low-energy building in Serbia. Beodom has been pioneering in the field of low-energy buildings in Serbia for the past 3 years and gained a lot of concrete experience. Her presentation can be accessed on the dedicated page for the event.

Milena Gojković-Mestre, Director of Beodom (photo Beodom).

Rehau

Rehau was at the fair to present its offering for the use of geothermal energy (heat pump and probes), solar energy (thermal solar panels), hesting/cooling distribution (underfloor and radiators) and piping.

Rehau stand at the SEEBBE 2010 (photo Beodom).

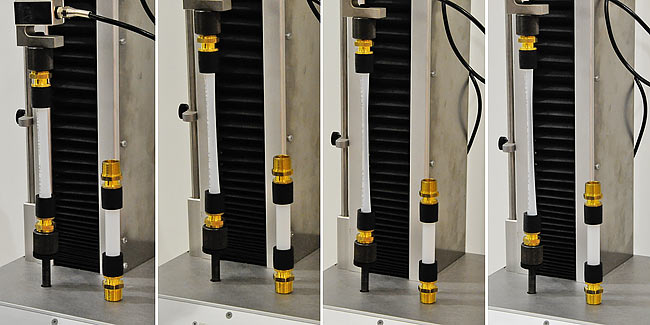

This year, Rehau introduced very interesting experiments to show the superiority of the PE-Xa (high density cross-linked polyethylene) pipes and fitting compared to alternative solutions. Dušan Todorović, Director of Rehau Serbia, kindly ran the experiments for us.

Rehau experiments on PE-Xa pipes. On the right, the experiment stretching the pipe, on the left, the experiment on the flow comparison (photo Beodom).

Stretching to the point

The first experiment was stretching a piece of PE-Xa pipes taken between 2 Everlock fittings (the standard Rehau solution for plumbing). The pipe would stretch from 6 to 7 times its length before to break. Yet, it would break somewhere in the middle and not on the fitting. The experiment demonstrates the fantastic property of PE-Xa and the resistance of the fitting.

Stretching a piece of PE-Xa pipe to the breaking point. The small pipe on the right is the same as the one being streched but in its original length (photos Beodom).

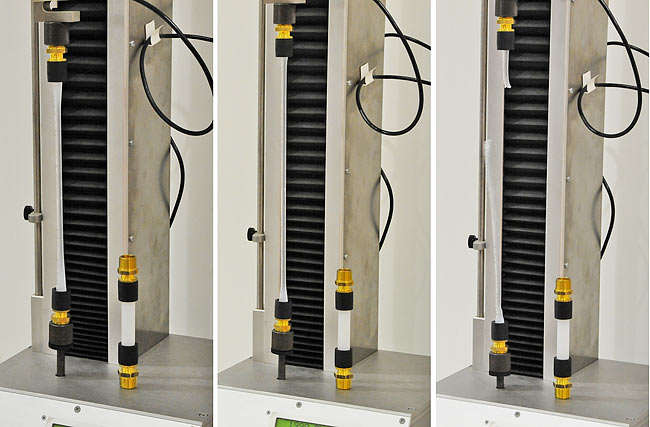

Warming up back to size

An even more remarkable experiment was the follow up of the previous one. Taking the longest part of the broken stretched PE-Xa pipe from the previous experiment, hot air was blown on it. Due to the remarkable properties of PE-Xa, the heated stretched pipe naturally shrink back to its initial shape. This method is actually used by installers to repair or bend PE-Xa pipes.

Shrinking the piece of streched PE-Xa pipe from the previous experiment back to its original size using a thermostat controlled hot air gun (photos Beodom).

Controlling the flow

The last experiment was to show the comparative flow going out of different pipes of same section. One big advantage of Rehau fitting system is the fact that it maintains the same flow as the one of the pipe it is made for. For instance, the fitting for a 16mm pipe, preserves the flow of that 16mm pipe. Most common competing fitting systems found in Serbia reduce the flow of the pipe. For instance, the fitting for a 16mm pipe provides a reduced flow equivalent to a 12mm pipe. This results in increased pressure at the point of the fitting and provides reduced performance.

Demonstrating the superior flow of Rehau PE-Xa system compared to other pipe systems of same section. The picture of the left shows the experiment. On the picture on the right, the left container was filled with another system while the right container was filled with Rehau system (photo Beodom).

In fact, Dušan Todorović demonstrated, using the same experiment, that a 16mm pipe in the Rehau system is equivalent to a 20mm pipe in other systems in term of flow coming out of the pipe.

Note that if you wish to see the live experiments, Rehau will be present at the International Fair of Technique and Technical Achievements, from 11 to 15 of May 2010, with the same experiments.

We also have a video from Rehau showing Rautitan pipes and fittings system under stress.

Zorka Opeka Klimabloc

Like last year, Zorka Opeka presented their Klimabloc line. Presentation was much better this year with more space and complete built walls with Klimabloc 38, 30 and 20.

Zorka Opeka stand at the SEEBBE 2010 fair (photo Beodom).

We had the chance to meet with Markus Pichler, Austrian owner of Klimabloc, to share our vision and experience of the Serbian market. National consciousness regarding energy efficiency and sustainable development has ineluctably started to move ahead in Serbia. We can feel the difference each passing year. Of course, Serbia has been very hard hit by the crisis and that has had a very negative impact for sale of construction materials.

Klimabloc 20 with insulation and facing brick and wall of Klimabloc 38 in the background (photo Beodom).

And to prepare for the need of tomorrow, Zorka Opeka presented the new Klimabloc 50. This extra large clay block allows to build walls that are 50cm thick with a U-value of 0.23 W/m²K. If Klimabloc 50 is new in Serbia, it is already well established in Austria. New energy efficiency norms are coming in place in Austria and Klimabloc 50 is the best answer to fully them.

Klimabloc 50, new in Serbia but already well established in Austria (photo Beodom).

The monolithic wall system, made of natural material such as clay, brings consistency in performance, thermal inertia, quality and durability and well being inside the finished construction. This is, in our opinion, incomparably better than solutions based on a thick external insulation layer made of polystyrene or mineral wool.

Liapor : expanded clay

We came across Liapor a very interesting company that is starting development in Serbia. Some of their products are already distributed in Serbia by Nimon d.o.o. Liapor is specialized in expanded clay.

Liapor - Nimon stand at the SEEBBE 2010 fair (photo Beodom).

Liapor produces expanded clay spheres of different sizes. Those clay spheres are burnt at a temperature of about 1200 °C in a rotary kiln. During the process the organic components of the clay burn and the spheres expand. The result are expanded ceramic small balls, very light, with very fine pores and completely natural.

Liapor expanded clay spheres (source Liapor).

Liapor expanded clay can be used as loose fill for thermal insulation or to produce lightweight mortars or concrete. But the most interesting application is the production of large construction blocks with excellent thermal characteristics. Liapor had some of them on display but there is no production in Serbia just yet. Apparently, an agreement is signed to start production of blocks 36,5cm thick in Serbia. We will definitely follow up on that.

Liapor expanded clay spheres (photo Beodom / Liapor).

Duco natural ventilation

We noticed that our partner Duco had this year a beautiful stand. Duco has a new logo and many new products covering all needs of ventilation and sun protection.

Duco stand at the SEEBBE 2010 fair (photo Beodom).